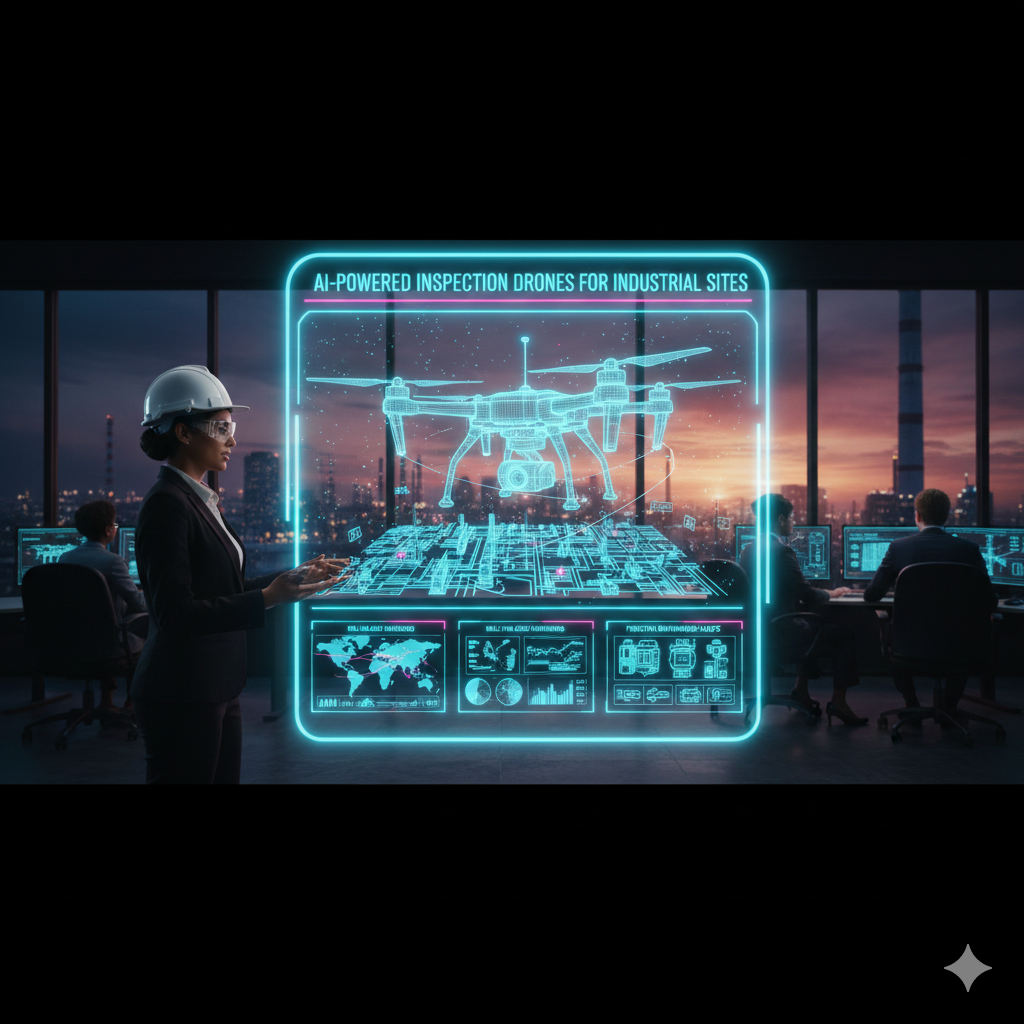

AI-Powered Inspection Drones for Industrial Sites

AI-Powered Inspection Drones for Industrial Sites

Industrial facilities, such as manufacturing plants, oil refineries, power stations, and construction regions, are required to undergo frequent inspections in order to guarantee safety, operational efficiency, and compliance with regulatory requirements. The manual tests that are a common component of traditional inspection procedures are not only time-consuming but also dangerous and prone to errors caused by human error. This procedure is being revolutionized by inspection drones powered by artificial intelligence. These drones combine autonomous flight capabilities with data analysis driven by AI, which enables industrial inspections to be carried out more quickly, with greater safety, and with greater precision.

The Operations of an Autonomous Drone

Drones that are powered by artificial intelligence are able to fly alone, demonstrating their ability to navigate complicated industrial situations without constant human control. By utilizing global positioning systems (GPS), LiDAR, and sensors that identify obstacles, drones are able to either follow pre-defined routes or dynamically adapt to changing situations. A reduction in the need for manual piloting is made possible by autonomous navigation, which enables inspection teams to cover broad regions in an efficient manner while simultaneously reducing the risk to personnel.

Methods of Data Collection and Analysis in Real Time

Inspection drones are able to gather enormous amounts of data in real time since they are outfitted with high-resolution cameras, thermal imaging, and multispectral sensors at their disposal. In order to identify anomalies such as structural damage, equipment wear, corrosion, leaks, or temperature irregularities, artificial intelligence algorithms rapidly analyze photos and sensor data when they are received. Through the use of real-time analysis, possible problems can be discovered in a timely manner, hence minimizing downtime and preventing minor difficulties from developing into significant failures.

Information Regarding Predictive Maintenance

Through the identification of early symptoms of equipment degradation or operational stress, inspection drones driven by artificial intelligence assist to the development of predictive maintenance programs. The purpose of machine learning models is to assess both past and current inspection data in order to anticipate future failures before they take place. Through the integration of drone-collected data with industrial maintenance systems, operators are able to arrange repairs in advance, thereby increasing the lifespan of equipment and enhancing its overall reliability.

Improvements in Safety While Decreases in Risk

It is common for individuals to be required to enter potentially hazardous regions during industrial inspections. These areas may include high-altitude structures, restricted spaces, or settings containing poisonous chemicals. Unmanned aerial vehicles (drones) minimize the requirement for human presence in hazardous areas, hence dramatically lowering the likelihood of accidents or injuries occurring. Artificial intelligence also improves safety by enabling the avoidance of obstacles, the creation of adaptive flight paths, and the implementation of automated emergency reaction protocols during inspections.

Achieving the Best Possible Inspection Coverage and Frequency

When it comes to determining the appropriate frequency and routes for inspections, artificial intelligence algorithms examine data pertaining to operations and the environment. Consequently, this guarantees that high-risk regions and important equipment are monitored in a consistent manner, without the need for excessive repetition. Utilizing optimized flight planning allows for time savings, a reduction in operational expenses, and the guarantee of thorough site coverage, all while maintaining high standards of both safety and performance.

Integration With Asset Management Systems and Industrial Internet of Things devices

The integration of inspection drones with Industrial Internet of Things (IIoT) networks and asset management platforms enables the sharing and analysis of data in a seamless manner. The data from real-time inspections can be linked to the records of the equipment, the maintenance schedules, and the operating dashboards. This integration offers a comprehensive perspective of industrial assets, enhances decision-making, and makes it easier to manage site operations in a proactive manner.

Innovative Methods for Identifying Flaws and Controlling Quality

In order to detect flaws or irregularities that human inspectors might overlook, drones that are powered by artificial intelligence make use of computer vision and machine learning algorithms. Drones are capable of providing extremely exact assessments, which might range from locating cracks in pipelines to locating components of machinery that are overheating. The detection of defects using automated processes guarantees constant quality control, minimizes the likelihood of errors caused by humans, and improves compliance with regulatory and safety standards.

Productivity in operations and cost-effectiveness of operations

In the process of site evaluations, drones driven by artificial intelligence reduce the need for manual inspections, which in turn reduces labor costs and minimizes downtime. Inspections may be carried out more quickly and on a more frequent basis, which enables preventative maintenance and helps to avoid costly repairs that were not planned for. Enhancing overall operational productivity and contributing to improved resource management are two outcomes that can be achieved through the integration of speed, precision, and automation.

Performance that is both continuously learning and adaptable

Drones that are powered by artificial intelligence are able to continuously enhance their inspection capabilities by learning from prior flight data, anomalies that have been spotted, and changes in the environment. The flight routes are refined, the sensor utilization is optimized, and the fault identification is improved over time thanks to adaptive algorithms. Continuous learning guarantees that inspection procedures grow increasingly more efficient and reliable over time, even as the surroundings in which they are carried out under industrial conditions change.

Inspection drones that are powered by artificial intelligence are transforming the administration of industrial sites by offering inspections that are autonomous, safe, and accurate. Real-time data analysis, insights into predictive maintenance, and connection with industrial systems are some of the ways in which these drones improve operational efficiency, safety, and quality control. As technology continues to improve, drones driven by artificial intelligence will become a vital tool for industrial operations. These drones will enable site management that is more intelligent, faster, and more proactive, while also cutting costs and decreasing danger.